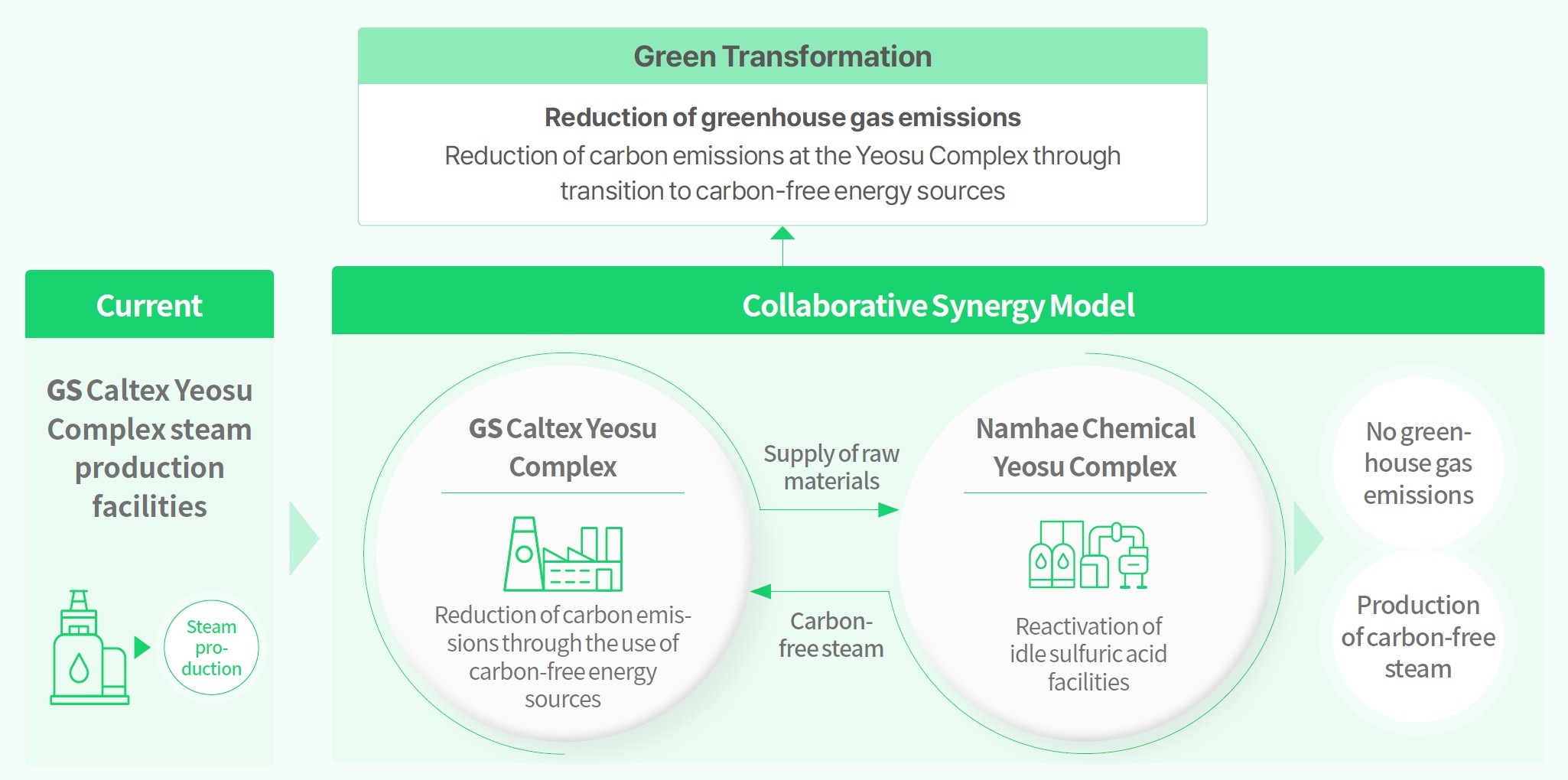

- Signed an agreement with Namhae Chemical on October 31 to introduce and supply carbon-free steam, with commercial operations targeted for 2027

- Replacing existing LNG-based steam with carbon-free steam in production processes

- Serving as a model case of value creation through collaboration within the Yeosu Industrial Complex

after signing the ‘Carbon-Free Steam Introduction and Supply Agreement’ at GS Tower in Seoul on October 31.

GS Caltex (CEO Saehong Hur) announced on November 3 that it had signed a ‘Carbon-Free Steam Introduction and Supply Agreement’ with Namhae Chemical on October 31 at the GS Tower in Seoul. The agreement marks tangible progress in their joint project just ten months after the two companies signed the memorandum of understanding in December 2024.

GS Caltex’s ‘Carbon-Free Steam Introduction and Supply Business’ involves reactivating Namhae Chemical’s idle sulfuric acid plant within the Yeosu Industrial Complex to produce carbon-free steam, which will be supplied to GS Caltex’s Yeosu Complex to replace its existing LNG-based steam.

Under the arrangement, GS Caltex will supply sulfur, a byproduct of crude oil refining, to Namhae Chemical, which will use it as feedstock to produce sulfuric acid. The exothermic reaction from this process will be harnessed to produce carbon-free steam without emitting CO₂. The resulting steam will then be supplied to GS Caltex.

GS Caltex anticipates this initiative will deliver annual carbon reductions of approximately 70,000 tCO₂eq1 compared to conventional LNG-based steam production.

The two companies plan to begin work early next year on the construction of steam pipelines, modification of Namhae Chemical’s sulfuric acid plant, and construction of new sulfuric acid storage tanks, with commercial operations planned for 2027.

Saehong Hur, CEO of GS Caltex, stated, “This collaboration exemplifies how companies can leverage their respective strengths to identify new opportunities for carbon reduction.” He added, “We look forward to growing together as trusted partners in shaping a more sustainable future for the industry.”

Going beyond the reactivation of idle facilities, the project stands as an exemplary case of companies in the Yeosu Industrial Complex developing a sustainable business model through close cooperation.

GS Caltex identified the opportunity while reviewing options for low-carbon energy transition at the Yeosu Complex through its Business Council, the companywide collaborative body for discussing and making decisions on future business initiatives. During the review, GS Caltex discovered that building a sulfuric acid plant using sulfur, a byproduct of crude oil refining, could enable carbon-free steam production.

Subsequently, a collaborative approach was developed to utilize Namhae Chemical’s idle sulfuric acid plant, also located within the Yeosu Industrial Complex.

Despite the complexity of integrating two distinct business components — feedstock supply and steam production and supply — the two companies collaborated to reactivate idle facilities, guided by their shared goal of reducing carbon emissions and developing new business opportunities.

- tCO₂eq (metric tons of CO₂ equivalent): a unit of measurement for greenhouse gas emissions. Because greenhouse gases have different warming effects, their impact is standardized and measured relative to CO₂. ↩︎